GE’S INDUSTRIAL INTERNET (OF THINGS AND SERVICES THAT IS)

May 13, 2015

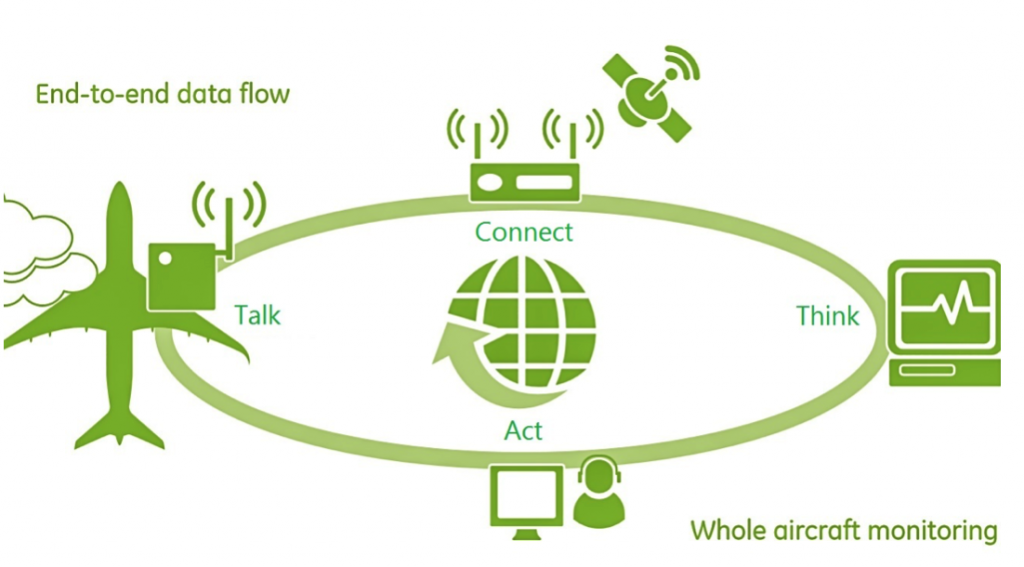

Adapted from “Integrated Vehicle Health Management – Connecting You with Your Aircraft,” General Electric 2010

Adapted from “Integrated Vehicle Health Management – Connecting You with Your Aircraft,” General Electric 2010

General Electric, famously co-founded by Thomas Edison, was one of the first companies to grasp the enormous innovation potential that an instrumented, connected and intelligent world would offer, and is acting decisively on the opportunities. GE’s Predix predictive maintenance platform belongs to today’s main hallmarks of what “connected things and services” can do in ecosystems of manufacturers, business partners, and customers throughout the economy – as GE operates through these seven segments: Power and Water, Oil and Gas, Energy Management, Aviation, Healthcare, Transportation, and Capital.

more–>

Integrated Vehicle Health Management

A fine example of General Electric’s appetite for industrial innovation is the development of the core Integrated Vehicle Health Management application (IVHM) for GE Aviation. From medical imaging, to aircraft engines, energy and rail monitoring, GE and its affiliates monitor hundreds of thousands different devices, including tens of thousand engines.

GE’s IVHM application now provides 24/7 worldwide wireless connection to aircraft health status in the broadest sense – including prioritized alerts and analysis of airframe, systems, and engines. The latter can be bought, leased and financed by General Electric Aviation Services (GECAS) from various companies, including GE, CFM, Rolls-Royce, Pratt & Whitney, IAE and Engine Alliance. GECAS offers short-term leases ranging up to one year, and operating leases up to a term of 20 years. The company provides the largest and most diverse pool of spare engines in the marketplace.

The many benefits of GE Aviation’s IVHM application that keep increasing include: reduced unscheduled and scheduled maintenance; reduced return to service time; reduced overall operations and maintenance costs; automatic data downloads for Flight Operational Quality assurance (FOQA) and health; quick identification of fleet-wide issues; improved aircraft availability and technical support; ever new insights to aircraft operation and performance.

Through this comprehensive web-based aircraft health management service, GE made it possible for operators to monitor fleet trends and detect and predict anomalies earlier and with greater confidence.

Advanced data transmission software enables a quick, smart and automatically updated 24/7 web connection between the customer base and the central data repository. GE’s IVHM uses artificial intelligence technology to learn from the data, enabling increased fault detection and prognostics that immediately halved the number of undetected faults when it was taken into production, back in 2010.

The Benefits of Predictivity for GE

Predix is GE’s software platform for the Industrial Internet. It enables asset and operations optimization by providing a standard way to run industrial-scale analytics and connect machines, data and people. Deployed on machines on-premises or in the cloud, Predix combines an industry-leading stack of technologies for distributed computing and big data analytics, asset management, machine-to-machine communication and mobility – all focused on what GE calls “Predictivity.”

Predictivity Industrial Internet solutions leverage connectivity, advanced analytics and innovative user experiences to advance assets and networks toward zero Unplanned Downtime and maximized productivity through Predictive Maintenance technology. With Predictivity, industrial organizations have better visibility into the past, transparency into the present and foresight into the future. Vertical-specific Predictivity solutions range from condition-based maintenance and asset life cycle optimization to fuel consumption management and plant automation.

No Blips in the Relationship

The “health” of products and services determines whether organizations, brands and applications are able to maintain an optimal relationship with their customer base or not. Therefore, in both industrial and consumer oriented economic environments, Predictive Maintenance in a broad sense is a key target to pursue, doing away with reactive maintenance and complaining customers. There should be no unplanned downtime or other inconvenience: no blips in the relationship whatsoever. In other words an optimal connected service experience!

English | EN

English | EN