Connect-Talk-Think-Act – IoT and IIoT for Grumpies

May 18, 2015

Although many grumpies will remain skeptical, the Internet of Things (IoT) and the Industrial Internet (of Things: IIoT) are “two of a kind” and have started to transform the ways in which enterprises operate, collaborate and engage with their customers. Today, a final “Internet of Anything” or just “Anything Internet” phase is playing out, marrying the consumer side and the industrial side of the Internet of Things through a myriad of connected services from within and beyond company boundaries. This lays the foundation of product as well as service innovation, intensified customer engagement, and even new business models and revenue streams.

Although many grumpies will remain skeptical, the Internet of Things (IoT) and the Industrial Internet (of Things: IIoT) are “two of a kind” and have started to transform the ways in which enterprises operate, collaborate and engage with their customers. Today, a final “Internet of Anything” or just “Anything Internet” phase is playing out, marrying the consumer side and the industrial side of the Internet of Things through a myriad of connected services from within and beyond company boundaries. This lays the foundation of product as well as service innovation, intensified customer engagement, and even new business models and revenue streams.

(I)IoT Benefits

The world has started to embrace this final phase of the “Anything Internet” paradigm: retailers, media, airlines, and car makers; insurance, telcos, product manufacturers, and software companies; transportation & logistics, cities, farmers, armies and individuals. Better products and services, new functionalities, faster customer feedback loops and value chains, a remarkable increase in innovation and startup activities, cross-industry benefits, and last but not least a healthier and more efficient human lifestyle are just a few generic highlights from the impressive longlist of applications that our sensorized IoT world has on offer.

Connecting the IoT Dots

Every major progress comes at a cost and the (I)IoT is no exception. Learning by doing, we today experience what it means to Connect objects, machines, devices, components and people; what these actors should Talk about; how we can let them Think with us and among themselves; and what Actions we deem necessary and desirable.

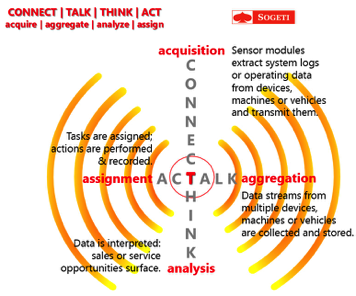

The architecture of any Internet of Things or Industrial Internet application consists of a four-tier structure in which the Connect phase immediately is the start of data Acquisition; the automated communication phase (Talk) corresponds with Aggregation of data; Think equals data Analysis; and Action follows upon the (automated) Assignment of tasks.

This Connect-Talk-Think-Act mantra is the concise way of explaining A) what the implementation of IoT solutions would mean in a specific context, B) which complexities and challenges arise, and C) how the simple CTTA mantra governs the more technical 5A scope of data Acquisition, Aggregation and Analysis, the automated Assignment of tasks, and the Actions to be taken.

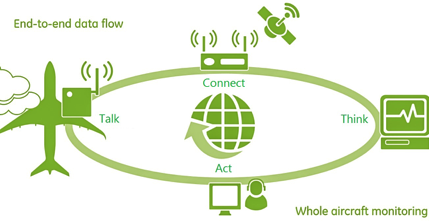

Just look at the illustration below. Originally, it read Connect-Detect-Collect-Direct instead of Connect-Talk-Think-Act but that may serve as an extra validation of our generic CTTA model.

Adapted from “Integrated Vehicle Health Management – Connecting You with Your Aircraft,” General Electric 2010

In my May 12 blog post, I presented GE Aviation’s integrated Vehicle Health Management application (IVHM, see picture) as a poster child. From medical imaging, to aircraft engines, energy and rail monitoring, GE and its affiliates monitor hundreds of thousands different devices, including tens of thousand engines.

GE’s IVHM application now provides 24/7 worldwide wireless connection to aircraft health status in the broadest sense – including prioritized alerts and analysis of airframe, systems, and engines. The latter can be bought, leased and financed by General Electric Aviation Services (GECAS) from various companies, including GE, CFM, Rolls-Royce, Pratt & Whitney, IAE and Engine Alliance.

The many benefits of GE Aviation’s IVHM application that keep increasing include: reduced unscheduled and scheduled maintenance; reduced return to service time; reduced overall operations and maintenance costs; automatic data downloads for Flight Operational Quality assurance (FOQA) and health; quick identification of fleet-wide issues; improved aircraft availability and technical support; ever new insights to aircraft operation and performance.

Through this comprehensive web-based aircraft health management service, GE made it possible for operators to monitor fleet trends and detect and predict anomalies earlier and with greater confidence.

Connect, Talk, Think and Act before the competition does

In contrast however, most companies today still only take action when the customer reports an issue. From a customer satisfaction perspective, reacting simply means being too late. Surveys show that 93% of companies today fail to anticipate and act preventively. Although the technology to avoid this is there, as well as innovative and often disruptive best practices and use cases that are just waiting to be copied in, many enterprises still wait for failure to happen and for the customer to report this before taking any action.

The situation is alarming: 99% of the data companies collect today is latent while many opportunities are wasted. Companies apparently do not know how to use data to create value, and also fail to see that there are loads of cost-effective opportunities for them to improve and serve their customer remarkably better.

Reactive service processes that are bound to cause dissatisfied and complaining customers typically are H2H2S (Human-to-Human-to-System): manual, prone to subjectivity, and therefore even extra time-consuming. If you recognize such situations, make sure to eliminate them before the competition does.

CSX: nine phases, five steps

Although most processes aiming at a better Customer Service eXperience (CSX) today are only semi-automated – involving sales people, field service technicians, and customer care employees – they already will make a huge difference in improved customer satisfaction. Across industries, these nine main Connect-Talk-Think-Act phases are typical of many practices today:

1 – A connected machine or device generates data that is transmitted using a machine data gateway.

2 – The data is aggregated and analyzed. When an anomaly is detected that can impact performance, a case is created.

3 – The knowledge base or expert system is queried to identify the “next best action,” e.g. skillset and part replacement.

4 – The integration with the knowledge base or expert system identifies the service level and response time.

5 – The integration with the HR system identifies the available co-worker with the proper skillset.

6 – The integration with the inventory or PLM system (Product Lifecycle management) ensures that the required part or service is available or ordered.

7 – A ticket is created and a task is being assigned.

8a – A field service technician receives an alert on his mobile device. He informs a co-worker who performs the task and records the result on his mobile device.

8b – Or, the sales or customer service agent receive a task in their CRM system (Customer Relationship Management). Then, sales sends an offer and/or customer support contacts the customer. The results are recorded in the CRM system.

9 – The resolutions are analyzed, and the knowledge base or expert system (see 3) is updated.

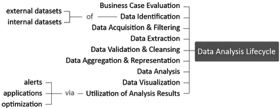

Digitally optimized connected services typically will relate to knowledge bases, expert systems, PLM and CRM systems – inside the enterprise and beyond its boundaries while tapping into partner ecosystems. Connect-Talk-Think-Act is a colloquial translation of the corresponding 5A cycle that includes these subsequent steps of data Acquisition, data Aggregation, data Analysis, the Assignment of tasks, and the required Action to be taken:

Step A1 – Acquisition. Sensor modules extract system logs or operating data from connected machines, devices or components and transmit the data. Some of these “connected things” generate data that is not transmitted, which requires extra action. Ideally, performance and usage data is acquired and transmitted every n seconds.

Step A2 – Aggregation. The operating data from from multiple connected things is collected, aggregated and stored. The data is visualized. Most machine data stored today is latent.

Step A3 – Analysis. Ideally, the data is being analyzed in real-time to identify issues. We distinguish between data visualization and analysis. When data is visualized, a person must monitor the data and decide if it is critical. This method is unreliable and subjective. Using historical and/or predictive tools, anomalies and issues can be automatically identified and set to trigger alerts. Only a fully automated approach is reliable, objective, and timely.

Step A4 – Assignment. When the data indicates an anomaly or when an issue is identifed that might cause a problem or represents an opportunity to eliminate dissatisfaction beforehand, ideally a case is automatically created. The most appropriate resolution is selected from the knowledge base or expert system, and assigned to the proper actor for handling.

Step A5 – Action. Interventions are performed to resolve the issue, and ideally the process is recorded and analyzed. The results should be fed into the knowledge base or expert system. In many cases today, the actor is a sales representative, field service technician, or customer care agent as in the following scenarios:

i. Customer Care provides the operator tips and instructions.

ii. Sales & Marketing proactively sends the customer offers and orders, and/or

iii. Technical Service is dispatched to perform maintenance or repair.

iv. The system sends messages, instructions and possibly software updates to the machine directly.

Consider these five A’s the core of a more detailed Data Analysis Lifecycle:

English | EN

English | EN