On June 23, an article titled, “The Data Dilemma and Its Impact on AI in Healthcare and Life Sciences” was published on IDC. In it, a general review was made about the state of adoption of technology by the healthcare sector.

The article discusses many relevant topics, amongst them I would like to discuss, IDC estimates that on average, approximately 270 GB of healthcare and life science data will be created for every person in the world in 2020. It is undoubtedly an interesting volume, especially if the population as a whole is considered, which seen from a business point of view, this is a great breeding ground for a multitude of startups that know how to extract the value of it. It is precisely for this reason that in recent months awareness has been raised and investment funds are accelerating the taking of positions in startups in the sector.

Going back from the individual to the company, from my experience, I believe that a very necessary step in the pharmaceutical industry is to advance in advanced analytical capabilities. It mentioned that each individual provides approximately 270 Gb of health data per year. But, what volume of information does a production plant generate? and what is being done with it? I will come back to this a bit later.

Another topic to highlight in the article is that where it talks about Real World Data (RWD) and how it can help improve the health of patients. For example, allowing to anticipate the diagnosis of diseases, as well as to better understand the possible relationships between pathologies and the genomic map and even end up promoting medicine à la carte. Undoubtedly solutions such as Confidential Computing promoted by Microsoft and Intel are especially helpful in building applications that keep data decrypted, even while using said data within the software system itself.

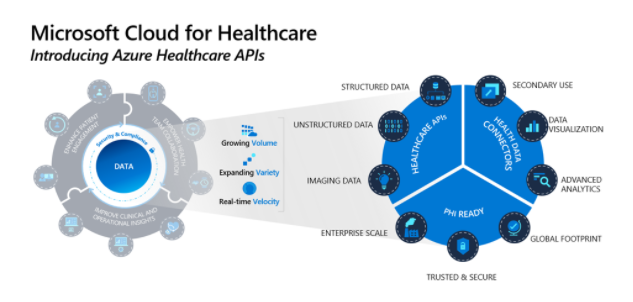

Just yesterday, Microsoft announced the expansion of the Microsoft Cloud for Healthcare portfolio by incorporating Azure API for FHIR which makes RWD accessibility a reality.

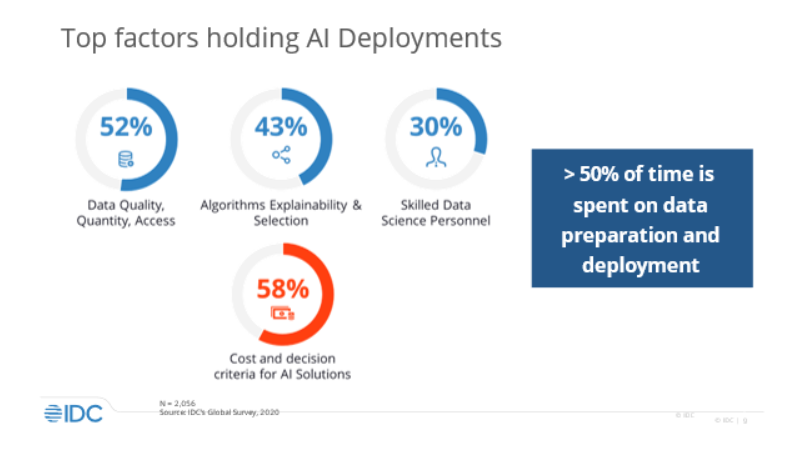

On the other hand, I liked how one of my reference phrases is mentioned: “garbage in is garbage out “. Phrase with special meaning in all this, since if we are not able to put together a solution that allows us to have quality data, what is built will have a fragile clay foundation as a base. Something that, according to 52% of those interviewed in the report, is recognized as a key factor.

I also wanted to highlight that I find it especially interesting to see that only 43% of those surveyed mention the Explainable AI as a challenge. I sincerely believe that it is mainly due to the fact that a good part of the projects are in an early stage and that the deep analysis of the decision algorithms is not yet a priority. Mention that in our case, at Sogeti we continue to improve the MLOps framework, incorporating solutions and strategies that provide informed details about why an algorithm decides what it decides. Quite a challenge, but 100% necessary, especially for Business people.

Coming back to the article, there are three points that generate special interest, the first is the possibility of using Artificial Intelligence for developing new drugs. As published a few days ago, DeepMind made a spectacular advancement in the identification of protein folding. Undoubtedly, this makes possible a great advance in the development of new drugs, as well as in the better understanding of the diseases themselves, especially the rare ones and syndromes. The second point of special interest is to apply the Digital Twins (Digital Twins) in the healthcare sector. This and the third, Advanced Analytics, go hand in hand.

Can you imagine being able to replicate a production plant in the digital world! Or not being so ambitious, at least one manufacturing or packaging line to be able to analyze both worlds in parallel and thus try to detect opportunities in the real world. Incredibly true!

Well, that begins to be a reality thanks to solutions such as Microsoft Digital Twins

With the bulk of information that a set of industrial machines can provide, together with the information extracted from the electronic production guides (EBR), as well as from the engineering maintenance plans and HVAC systems of the plant, enables us incredible possibilities of process optimization and improvement of final yields. Thus resulting in an increased productive margin due to the elimination of wastage, everything sounds very Lean , right? 😉

Finally, technology is advancing at such a fast pace that it is very difficult to keep up with everything. That is why it is particularly important to have multidisciplinary teams dedicated to in-depth analysis. Many of them help in co-creation and sharing practical knowledge which in turn leads us to solutions such as our SogetiLabs , an Open Innovation laboratory . Do you have a challenge? Here we are!

English | EN

English | EN