The IT-product lifecycle

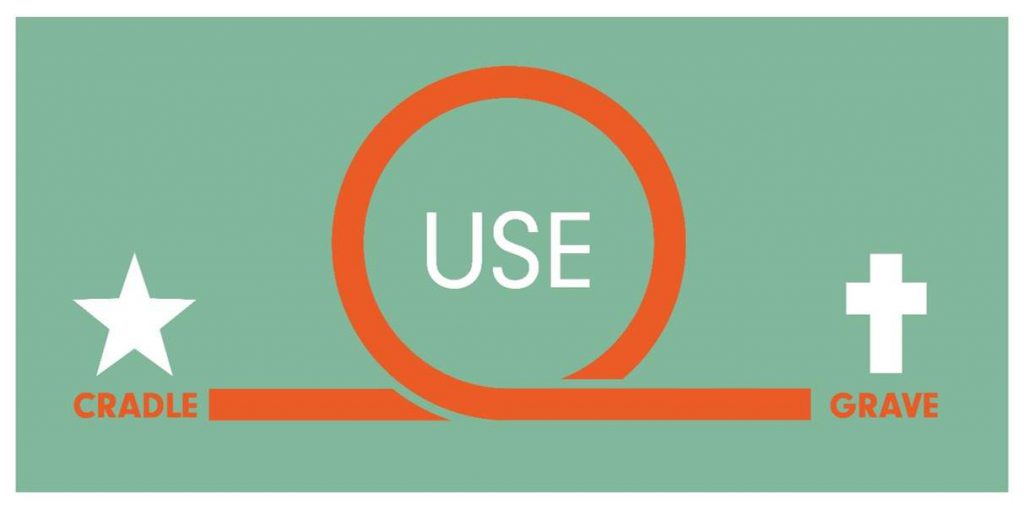

Every IT product has a lifecycle from cradle to grave. To ensure creating business solutions that contribute to business success an integrated process of Product Lifecycle Management (PLM) is needed. To succeed, PLM must be frontloaded with quality measures instead of checking quality at the end and wasting effort, money and precious time on fixing defects. To achieve this the organization needs a new and integrated way of collaboration between people using relevant, adequate and integrated tools to minimize efforts and work towards implementing the business solution in a way that gives confidence that the business value will be achieved, both on the short and long term. This goes for traditional digital systems but just as well for systems that use artificial intelligence, robotics or any other new technology. Managing the activities during this lifecycle often is very challenging. The product lifecycle spans a very long time in the case of digital manufacturing machines. Figure 1 The product lifecycle from cradle to grave.

Figure 1 The product lifecycle from cradle to grave.

Cradle

The process to create a new digital system often has many different activities that may be performed sequentially or in parallel. Amongst these activities there need to be quality assurance activities such as testing. Very important to bring the development up to speed is to have early quality measures, such as reviewing requirements, designs, models and/or user stories.Use

Systems in the manufacturing industry may have a very long maintenance period during which changes must be monitored. In Product Lifecycle Management, many different systems are used to record all relevant data about the development process. The connections and exchange of all data is often a challenging process for which the use of tooling is inevitable. The use of AI-powered tools is a very promising way of improving this monitoring of the process as well as an improvement of the efficiency of the quality assurance and the product lifecycle activities as a whole. AI-powered dashboards enable a continuous monitoring of the system during its lifecycle and can show when activities have an effect that goes beyond previously set thresholds or tolerances.Grave

Every digital system at one point in time will be retired. Although switching off (parts of) a digital system may seem like a trivial action, in reality retiring a system is a complex process. Digital systems have an Information and operational part. Also called the IT and OT. Switching of an OT part (hardware) impacts the IT part (software). For example, the IT part continues with new OT systems. Retiring hardware also includes making sure there’s a new system, converting the relevant content to the new system but also making sure the history of the system is preserved. Migration is the term often used in this context. AI has good use in migration projects. AI is helpful for disclosing historic data, especially when it is stored in raw format. This is also known as digital archeology.Digital archeology and testing

With the increasing speed of evolution of information technology, we also see an increase in the speed of retirement of products, systems and technologies. One aspect is storage technology. Due to legal regulations companies need to be able to keep their systems of record accessible for a certain period of time. The actual time differs per country and industry, but a period of a decade is very common. Back in the 1970s when all administrative work was done manually it was easy to keep an archive accessible. Just store the ledgers in a safe place and when demanded retrieve it and hand it over to the interested party such as the tax office. Nowadays, keeping an administrative system accessible for a decade is a very challenging task. Remember that it’s just a decade ago that the CD-ROM replaced the Diskette (or floppy disk) and already today it’s hard to find a computer that still has a CD-ROM drive. And another thing is the software. Companies regularly switch database systems or their ERP software. After such a system retires, they may still have the data, but they don’t have the software to interpret the data. And this is where digital archeology comes in. It generally has two stages:- Retrieve the data

- Interpret the data

Product Lifecycle Management

During the product lifecycle, there are basically four interacting activities. They are shown (counter-clockwise) in the holistic view of Figure 2. Figure 2 The four-segmented holistic view of creating and implementing business solutions.

Using this holistic model helps us to improve. The improvement has two focus areas:

Figure 2 The four-segmented holistic view of creating and implementing business solutions.

Using this holistic model helps us to improve. The improvement has two focus areas:

- Manage and improve the product quality throughout the entire product lifecycle

- Improve the efficiency and effectiveness of the activities in the lifecycle process

English | EN

English | EN