3D DIGITALIZATION IN INDUSTRIAL WORLD

February 10, 2017

I started working in Engineering Services in the year 1998. Having worked over time with various products and companies, I have observed two mixed trends evolving side-by-side in this industry:

- On the one hand, the ever-increasing volume and complexity of technical data, the need to demonstrate compliance with a tougher and more detailed set of regulatory requirements and the increasing amounts of business partners that each company has to control. Cumulatively, all these three factors have come together to create a much more complex business environment today, in which companies need to be able to anticipate and solve problems pro-actively, bring burgeoning costs under control and be flexible and agile.

- On the other hand, the physical world is still weighed down by the burden of legacy. Legacy basically refers to old standards, formats or technologies (For example, lots of product definitions and certifications are still based on 2D-drawings). The problem is that legacy technology is not evolving at the same rate across different portions of the value chain, thus leading to instances of mismatched standards and the need for expensive rework. For example, today, most companies use digitalization or 3D technologies in the engineering phase but do not have similar tools in the manufacturing phase. In an ideal world, the definition dossier which the engineering departments prepare ought to be used ‘as is’ by the manufacturing department. However, this is often not the case as most manufacturing departments are still working with 2D drawings and need to re-work on the design inputs before they initiate product industrialization.

These trends point to the need to support and improve the physical world. In particular, there is a need to:

- Manage and coordinate technical data across the different product lifecycle stages, ensuring accessibility, integrity and continuity of this data, no matter what its origins or interactions in terms of actors and skills.

- Identify and develop new ways of working to improve operational performance (reduce time to market, secure cadence ramp-up, eliminate recurring costs, and maximize production continuity…)

For instance, AIRBUS A350- the last aircraft developed by Airbus is completely based on 3D digital mock-up enabling a substantial reduction in cycle development time, whereas the A320 is still based on 2D drawings at a time, when cadence ramp-up from 43 aircrafts to 60 aircrafts per month is becoming mandatory. The challenge for AIRBUS is not only to re-design legacy or new products engineering but also to onboard the entire product lifecycle to maximize benefits and ROI in this increasingly complex environment.

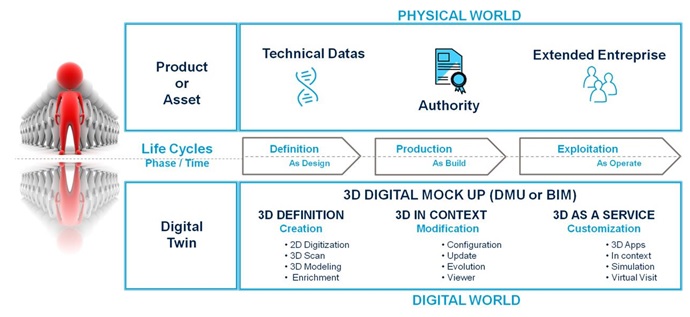

The answer to all of these challenges is Digitalization. The first step here is to create what is known as a digital twin which is basically a virtual representation of your asset, your product, all along its cycle, with intelligent and dynamic data modeling. To illustrate how this helps let us look at the diagram below:

. By providing a virtual representation of your entire lifecycle it allows you to anticipate challenges, drive better decisions and increase the efficiency of your operations. This digital twin concept is based on 3 pillars:

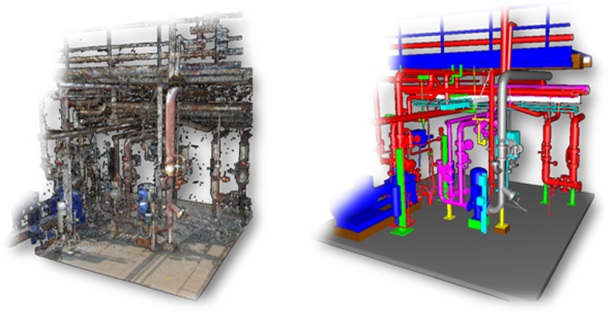

– 3D definition: This involves utilizing the best technology & process to capture the real-world and create a 3D definition. The best solution could be 3D laser scanning to extract numerical definition of the physical world by generating a points cloud representation which can then be used as a basis to create 3D model.

Points cloud 3D Model

– 3D in context: The ‘3D twin’ needs to be able to manage various modifications, evolutions, and configurations of the product or the asset. The 3D in context pillar aims to put in place an intelligent and dynamic data modeling, which has the capability to be enriched by updated and configurable data directly in the 3D model (tolerancing, annotations, 2D-Drawings, definition dossier …).

– 3D as a service: The aim is to customize 3-D model and extract what can be used to anticipate operations and take decisions when placed in different contexts. Essentially, this is stage at which the best value-add is created. Starting from a unique, continuous and robust technical data representation thanks to the enriched 3D-model, the aim of this pillar is to customize 3D functionalities to propose services to each actor of the product lifecycle in a way that will improve operational outcomes.

For example, one can provide quality inspectors with 3D product representation (“simplified 3D”) on a tablet to support them in their duties. This could also incorporate augmented reality which helps them superimpose 3D representation of the product on the physical product itself. Equipping inspectors with such technology is bound to accelerate digital twin added value to anticipate, simulate and solve operations complexity with concrete performance improvements (lead-time reduction, non quality reduction, costs reduction …).

Examples of “3D as a service” opportunities for Industry thanks to Augmented Reality

One of the key benefits of creating a proper digital twin, or more generally, of using 3D digitalization technology is the enablement of numerical continuity. Numerical continuity basically means the ability to create a single virtual model of a product or an asset covering its entire lifecycle. This provides a common language for creating, modifying and customizing technical data across the organization. This common language allows different stakeholders to work together much more smoothly and solves problems related to silos and duplication of work. It also definitively guarantees the quality and integrity of the data while enabling extended services as simulation and mobility for securing operational efficiency.

Digital twin creates and leverages numerical continuity by:

- Aligning technical data & processes all along the product lifecycle.

- Bridging gaps in the lifecycle to improve product/process/resources collaboration (the illustration below (from the Energy sector) depicts the required continuity which has to be implemented between engineering and operations in order to achieve this, cf below diagram).

- Customizing virtual applications & scenarios enabling profitable decision-makings in the physical world.

This is the reason why, we, at Sogeti/Capgemini are pushing 3D digitalization across all stages of the lifecycle. While this blog introduced you to the context and the need for this digitalization as well as the expected benefits, the next blogpost will basically go into greater details and concrete use cases on the digitalization process itself.

Do reach out directly to me frank.pacou@sogeti.com for any questions or comment in the section below.

English | EN

English | EN