NUMERICAL SIMULATION AS PRODUCT SCULPTURE “TOPOLOGICAL OPTIMIZATION”

November 5, 2013

Numerical Simulation is definitively a powerful mean to help our industrial customers to design and develop their product.

In the past, without this computer power, Design Office develops their product thanks to empiric and analytical methodologies where expertise and pragmatism converge to impressive results.

One of most famous example is aeronautic products, where engineers develop innovative aircrafts. Concerning structural parts, they design, size, and develop reinforced architecture, they definitively certify under Authority Airworthiness by physical tests.

Now, with the development of computer power and Numerical Simulation means, new opportunities are offered to our customers to accelerate and consolidate innovative solution for their products.more–>

Topological Optimization is one of this mean: complicated name, but in fact methodology and tool which allow you to sculpt the architecture of the product:

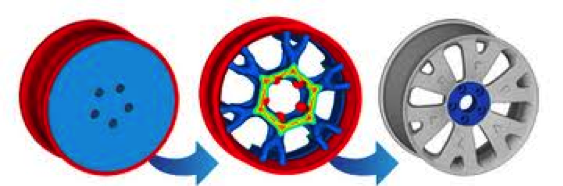

- You define a material block or free volume and you discretize it in elementary block

- According to a list of constraints and objectives, topological optimization determine if you need or not this elementary block.

- The sum of theses elementary results give you a proposal of shape, of architecture.

Below, an example of topological optimization process on hubcap:

Fortunately, topological optimization retrieves lots of architecture, already imagined and designed thanks to the creativity and sensitiveness of experienced Designers, without any numerical support. Nevertheless, in other case, topological optimization is source of innovation by proposing new architecture to reach objectives as design to cost reduction, design to build, weight breakdown savings…

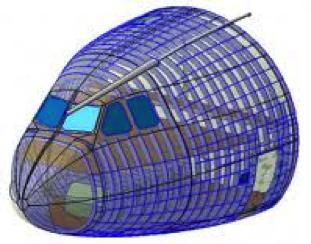

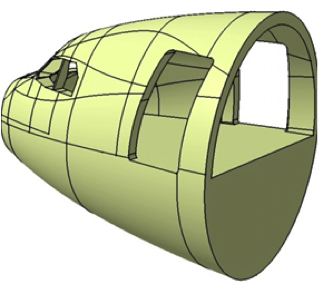

For example, aircraft nose fuselages are classically sized and strengthen thanks to horizontal and vertical stiffeners.

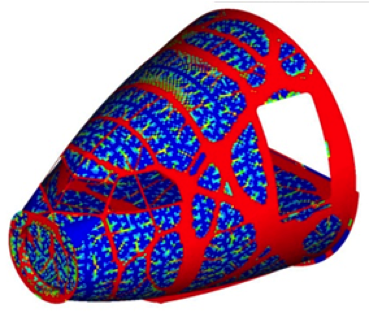

Several topological optimizations on Nose Fuselage propose innovative design principles, first by demonstrating that the direction of the stiffeners, not automatically in vertical or horizontal direction, but rather angled, is key parameter, and secondly by consequence, showing that all the horizontal and vertical stiffeners are not all necessary. This example illustrates numerical simulation as way of weight breakdown optimization directly impacting Aircraft Performances.

In no case, topological optimization will replace physical analysis and experience of designers, nevertheless this tool represents definitively a source of inspiration to create and develop architecture product of tomorrow.

And what about the potential link which could be created between this solution of product definition and new technology as 3D printing? New Generation of 3D aircraft!?

English | EN

English | EN